Audit-Ready. Margin-Protected. Execution-Aligned.

Most suppliers don’t fail audits because they lack quality systems. They fail because they lack execution control. For 60–90 days before an audit, teams scramble: pulling spreadsheets, chasing...

In today’s ultra-competitive automotive supply chain, margins are tighter and expectations are higher than ever. Whether you’re a Tier 1 powertrain supplier or a Tier 2 electronics manufacturer, finance and sales leaders share a common challenge: delivering profitability with predictability. If you feel like margin performance sometimes slips through the cracks, you’re not alone, and more importantly, you can do something about it.

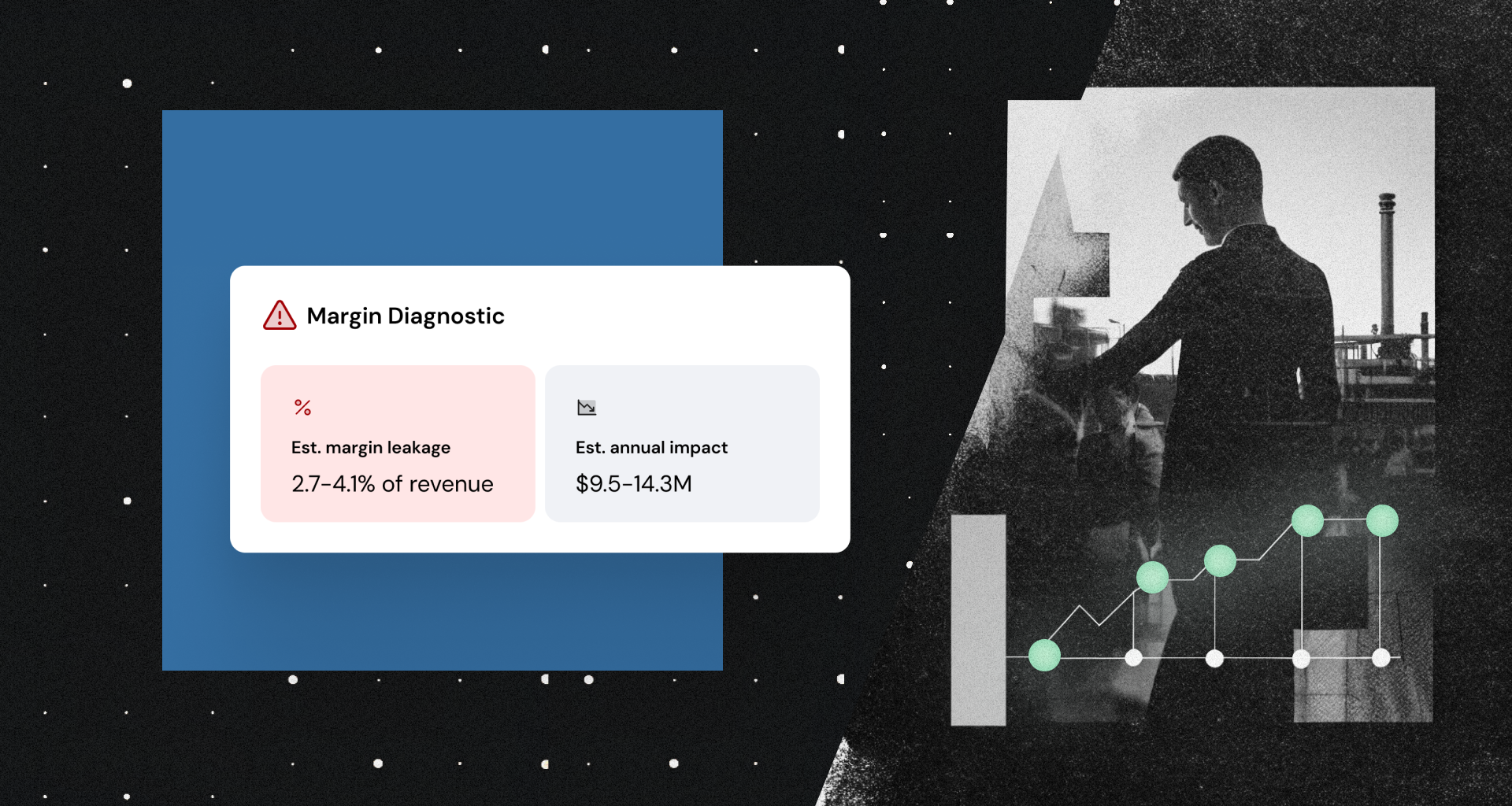

That’s where the Campfire Margin Diagnostic Tool comes in. Built for automotive suppliers who need to see what’s really happening inside their business, this free diagnostic helps teams pinpoint profit erosion, quantify risk, and align sales and finance to act with urgency.

Let’s explore why this matters, and how teams are using this diagnostic to shift from reactive firefighting to strategic margin growth.

Finance teams in automotive and manufacturing are no strangers to cost models, standard costing, and variance analysis. But in complex multi-tier supply chains, traditional approaches can fall short because:

For a CFO or VP of Finance, this means your annual budgeting and forecasting processes can quickly become obsolete.

Meanwhile, sales leaders are often judged on revenue growth and quote wins, not margin outcomes. Yet every proposal you send, every pricing concession you make, has a direct impact on company profitability.

The key insight? You can’t manage what you don’t measure accurately and in real time. The Margin Diagnostic Tool bridges that gap.

Designed specifically for automotive suppliers, the tool helps teams:

Whether you’re assessing an entire product line or a specific customer program, the diagnostic throws light on:

This isn’t just cost accounting data, it’s competitive intelligence for your internal business.

One of the biggest disconnects in supplier organizations is misaligned KPIs between finance and sales:

By surfacing clarity around margin impact per opportunity, both teams speak the same language. This fosters collaboration instead of tension.

The tool presents margin diagnostics in an intuitive, comparable format, so you can:

This helps reduce reliance on static spreadsheets and manual processes that are slow and prone to error.

Imagine this scenario:

A Tier 2 electronics supplier is struggling to hit margin targets despite growing revenue. The VP of Finance suspects margin erosion on specific programs, but the sales organization insists pricing concessions were necessary to win business. Using the Margin Diagnostic Tool:

This clarity transforms budgeting meetings from guesswork to strategic planning.

Another example involves quoting cadence alignment. Long quote approval cycles and outdated cost inputs can cause pricing to lag behind reality, a common issue in mature automotive businesses. The tool exposes these timing gaps, enabling teams to tighten cadence and reduce margin slippage.

According to Deloitte’s analysis of automotive supplier trends, companies that adopt advanced profitability and analytics tools outperform peers in price realization and cost optimization, especially in volatile markets with supply chain disruption. (For more context on this trend, see Deloitte’s Global Automotive Supplier Study.)

At Campfire, we see two recurring themes among leaders who outperform:

The Margin Diagnostic Tool accelerates both.

Whether you’re a financial controller seeking clarity or a sales leader striving for higher price realization, the Margin Diagnostic Tool is designed to fast-track margin intelligence.

Ready to diagnose your margin signals?

And once you’ve identified opportunities for improvement, continue your journey with these powerful Campfire modules:

Together, these tools help your organization turn complexity into clarity, and performance into profit.

In the automotive supply chain, margin leaks aren’t always obvious, but they are measurable. By adopting diagnostic tools, finance and sales leaders can uncover actionable insights, streamline decision-making, and build a shared understanding of profitability drivers.

Profitability isn’t an accident, it’s engineered. And with the right diagnostic and operational discipline, your team can predict margin outcomes rather than react to surprises.

Take the diagnostic today and start leading with margin intelligence.

Most suppliers don’t fail audits because they lack quality systems. They fail because they lack execution control. For 60–90 days before an audit, teams scramble: pulling spreadsheets, chasing...

Across manufacturing organizations, especially complex automotive suppliers, one problem keeps showing up in different forms: Finance says margins are eroding. Sales says deals were quoted correctly....

For Tier 1 and Tier 2 automotive suppliers, materials represent the single largest and most volatile cost line on the P&L. Steel, resins, aluminum, copper, chemicals, energy inputs, small swings...